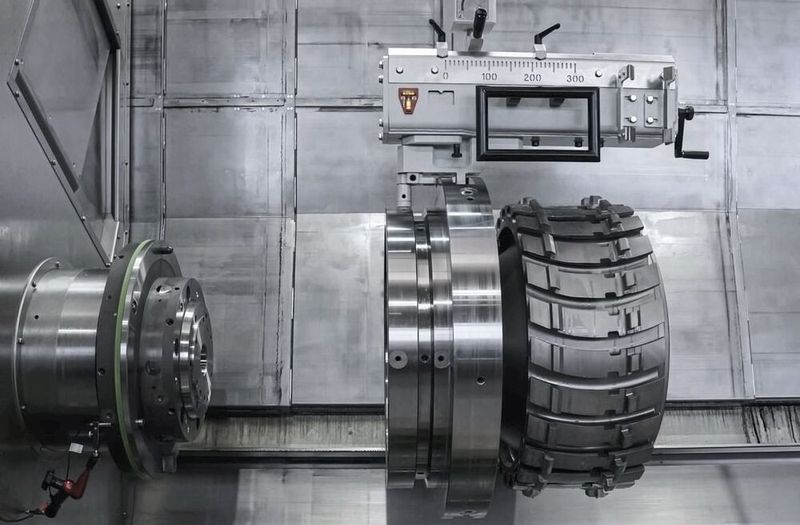

Complete Machining Complete Horizontal Machining of Chuck Parts

The complete machining of chuck parts in the aerospace sector is a core competence of WFL. The latest developments enable the complete machining of chuck parts up to 2000 millimeters (approx. 80 inches) in diameter.

When machining chuck parts, most manufacturing specialists likely think of vertical machining. And indeed, the vertical machining of chuck parts, especially ring- and disc-shaped parts, has some advantages, primarily the convenient loading and unloading of workpieces. However, chip removal in vertical machining often proves to be very problematic, with chips and coolant frequently remaining in the workpiece and disrupting the machining process. Here, horizontal machining offers significantly better conditions. Additionally, horizontal machining provides several productivity advantages, such as the use of a second tool carrier and a counter spindle.

Sign in or register and read on

Please log in or register and read this article. To be able to read this article in full, you must be registered. Free registration gives you access to exclusive specialist information.

Already registered? Log in here

:quality(80)/p7i.vogel.de/wcms/17/2a/172a787cba17118cca23678a068ec05e/0129235554v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/ab/e4/abe42d4ff8c461f601d4bce6a10dba1e/0129214964v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/e7/6a/e76a2e9c3042ae7b4ac583349b222c6a/dollar-544956-1920-1920x1080v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/93/1f/931f9289c146b87bfc571af18c6e62dc/abb-00-1772x996v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/1c/90/1c909a6a0c80f73a5f280a407041f811/ecoclean-fb-20hpo-1-v-2100x1181v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/5b/56/5b5641950ea23698ed573826fa124059/t4748s-2400x1349v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/a8/0d/a80d68ff622fc01952ee53a75d220f53/syt-20hd-20600-20stecker-20--205zu4-202500-20x-201977-2700x1519v1.png)

:quality(80)/p7i.vogel.de/wcms/c1/80/c180ace150e784fb8ff6af01cd569c18/202201-006-600-cern-1920x1080v1.png)

:quality(80)/p7i.vogel.de/wcms/eb/ef/ebef7eadac9d46e8bac69abeff423c38/rheinmetall-luna-ng-a30822de-850x478v1.png)

:quality(80)/p7i.vogel.de/wcms/5a/5e/5a5ee37b363a7ca06e69d8e8a5820d31/aribus-20skynopy-454x255v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/9e/8b/9e8b37c0ccf87d1d69805d0639dcad9d/launch-vehicle-spectrum-at-andoya-space-c-isar-aerospace-2026-01-30-083741-ruml-4007x2254v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/b3/da/b3dab43a52a2d38e349cc6d7b46c4985/close-up-irus-comp-00000-1366x768v1.webp)

:quality(80)/p7i.vogel.de/wcms/a2/83/a2834934b7b64c86a2071c7d40deab79/evolution-wifi-3840x2158v1.png)

:quality(80)/p7i.vogel.de/wcms/3b/30/3b306e8e4a378f13cdb12b3107c5c642/curtiss-wright-2026-425x239v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/07/0f/070f2f6a28e954422c60a0e15cb73471/0128576617v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/2b/f9/2bf900b5ce266b0407709cc936482482/0128247466v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/0d/a0/0da03913dcae9f6d52d63bb046163a4d/1-2026-01-23-14-41-53-478-1275x717v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/f4/2d/f42d58935394a644250ee0ae826c3c4e/asul-effektorcontainer-732x412v1.webp)

:quality(80)/p7i.vogel.de/wcms/7d/91/7d9177cdeae2a4d0e2a429a9d3e1bf9b/airbus-992x558v1.png)

:quality(80)/p7i.vogel.de/wcms/9e/d2/9ed26d1fea971818e76545fe78858bfc/opex-2026-portugal-4087x2301v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/67/4c/674c54baa745be497cecb716826af339/stahlwille-hero-1807x1016v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/0d/01/0d01a051ba894332a8091e3a3f9394e1/hytorc-defense-solutions-boxersatz-1899x1068v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/f1/ab/f1ab7543976a5ac7364579f3106a3774/-e2-80-8b-e2-80-8bground-20container-20system-20for-20the-20eurofighter-20weapon-20system-20phot-20hensoldt-20agclipboard-07-25-2025-01-1022x575v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/df/51/df515af8bbf143620acdd03a32870e10/yukondtk-3142-img-6096-gh-bauteil--20retuschiert-komprimiert-5001x2814v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/ed/46/ed468e77e44476536aa35cff03d0dd54/nhp6300-c-dnsolutions-4880x2744v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/92/3c/923c7f8a109960ecc0fb5b164bd0d1f9/0116595561v1.jpeg)