Welding World's Largest CFRP Aircraft Fuselage Segment Joined

Related Vendor

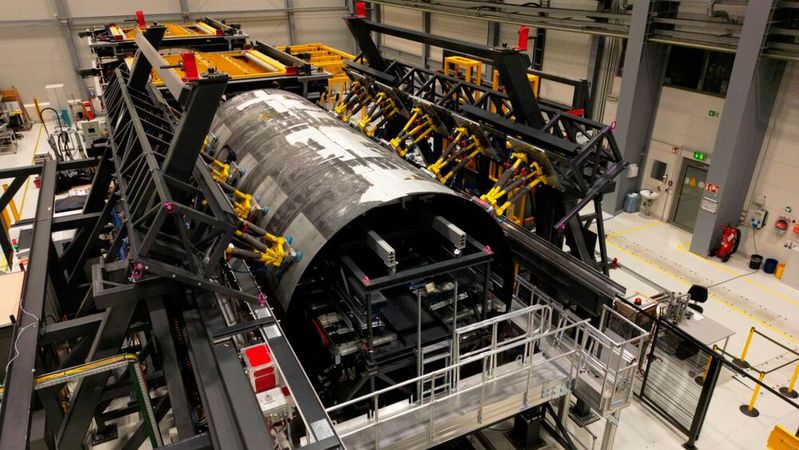

Employees of the Fraunhofer Society, together with international project partners, have manufactured the world's largest thermoplastic CFRP aircraft fuselage segment as part of the EU-funded Clean Sky 2/Clean Aviation project Large Passenger Aircraft (LPA). Instead of relying on previous riveting methods, the CFRP half-shells were welded dust-free.

To conserve resources, climate-friendly solutions are needed for the production and operation of passenger aircraft. Alongside new propulsion technologies, structural weight and manufacturing effort are also in focus. Both can be reduced through new construction methods: thermoplastic CFRP materials are one solution. As part of the EU-funded Clean Sky 2/Clean Aviation project Large Passenger Aircraft (LPA), project participants have, for the first time, manufactured a full-scale fuselage segment using thermoplastic CFRP materials to comprehensively evaluate the feasibility as well as the ecological and economic advantages and disadvantages.

Sign in or register and read on

Please log in or register and read this article. To be able to read this article in full, you must be registered. Free registration gives you access to exclusive specialist information.

Already registered? Log in here

:quality(80)/p7i.vogel.de/wcms/17/2a/172a787cba17118cca23678a068ec05e/0129235554v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/ab/e4/abe42d4ff8c461f601d4bce6a10dba1e/0129214964v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/e7/6a/e76a2e9c3042ae7b4ac583349b222c6a/dollar-544956-1920-1920x1080v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/93/1f/931f9289c146b87bfc571af18c6e62dc/abb-00-1772x996v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/1c/90/1c909a6a0c80f73a5f280a407041f811/ecoclean-fb-20hpo-1-v-2100x1181v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/5b/56/5b5641950ea23698ed573826fa124059/t4748s-2400x1349v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/a8/0d/a80d68ff622fc01952ee53a75d220f53/syt-20hd-20600-20stecker-20--205zu4-202500-20x-201977-2700x1519v1.png)

:quality(80)/p7i.vogel.de/wcms/c1/80/c180ace150e784fb8ff6af01cd569c18/202201-006-600-cern-1920x1080v1.png)

:quality(80)/p7i.vogel.de/wcms/eb/ef/ebef7eadac9d46e8bac69abeff423c38/rheinmetall-luna-ng-a30822de-850x478v1.png)

:quality(80)/p7i.vogel.de/wcms/5a/5e/5a5ee37b363a7ca06e69d8e8a5820d31/aribus-20skynopy-454x255v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/9e/8b/9e8b37c0ccf87d1d69805d0639dcad9d/launch-vehicle-spectrum-at-andoya-space-c-isar-aerospace-2026-01-30-083741-ruml-4007x2254v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/b3/da/b3dab43a52a2d38e349cc6d7b46c4985/close-up-irus-comp-00000-1366x768v1.webp)

:quality(80)/p7i.vogel.de/wcms/a2/83/a2834934b7b64c86a2071c7d40deab79/evolution-wifi-3840x2158v1.png)

:quality(80)/p7i.vogel.de/wcms/3b/30/3b306e8e4a378f13cdb12b3107c5c642/curtiss-wright-2026-425x239v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/07/0f/070f2f6a28e954422c60a0e15cb73471/0128576617v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/2b/f9/2bf900b5ce266b0407709cc936482482/0128247466v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/0d/a0/0da03913dcae9f6d52d63bb046163a4d/1-2026-01-23-14-41-53-478-1275x717v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/f4/2d/f42d58935394a644250ee0ae826c3c4e/asul-effektorcontainer-732x412v1.webp)

:quality(80)/p7i.vogel.de/wcms/7d/91/7d9177cdeae2a4d0e2a429a9d3e1bf9b/airbus-992x558v1.png)

:quality(80)/p7i.vogel.de/wcms/9e/d2/9ed26d1fea971818e76545fe78858bfc/opex-2026-portugal-4087x2301v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/67/4c/674c54baa745be497cecb716826af339/stahlwille-hero-1807x1016v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/0d/01/0d01a051ba894332a8091e3a3f9394e1/hytorc-defense-solutions-boxersatz-1899x1068v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/f1/ab/f1ab7543976a5ac7364579f3106a3774/-e2-80-8b-e2-80-8bground-20container-20system-20for-20the-20eurofighter-20weapon-20system-20phot-20hensoldt-20agclipboard-07-25-2025-01-1022x575v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/df/51/df515af8bbf143620acdd03a32870e10/yukondtk-3142-img-6096-gh-bauteil--20retuschiert-komprimiert-5001x2814v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/0a/d3/0ad3f61da1f9761268a38c0832d2248f/0119573504v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/60/76/60768e26a364208f1762f5b746bf8b5d/0124414503v1.jpeg)